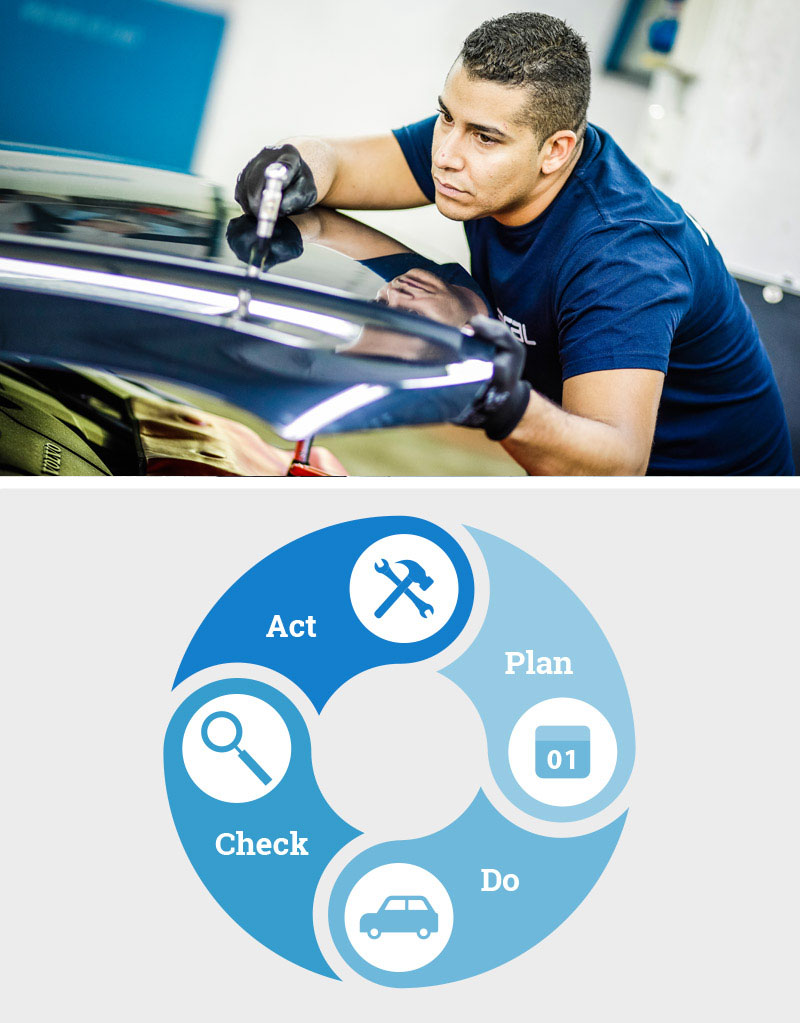

ARAL relies on a disaster management system able to anticipate every need thanks to its efficiency. In over 40 years of activity, the ARAL method has been perfected to go beyond simple restoration: attention to detail and high specialization today guarantee a level of Customer Satisfaction of the highest level.

The ad hoc planning of each phase of the intervention makes it possible to adapt the operating flow according to the objectives required by each client. All restoration operations, regardless of the type of damage, are however bound to a succession of phases necessary to achieve ARAL standards:

- damage inspection

- study of work spaces

- analysis of processes and times

- cost analysis

- study and implementation of the data analysis / reporting security plan

- flow management

- parts management

- personnel Management

- post service

All phases of the ARAL method are constantly monitored through the ARALGEST project management software.

Synergy

ARAL integrates itself into the industrial processes of the main OEM groups, interfacing with risk management departments to propose the most effective solutions. Close cooperation with quality and logistics departments is essential for achieving operational excellence and ensuring:

QUALITY

ensuring the end customer a product consistent with the usual quality standards

SHORT TIMES

delivering the product quickly, without delay or additional waiting

COST REDUCTION

planning the optimization of work and a careful prevention of extra costs

ARAL commits to achieving the pre-established contractual terms, operating with respect and confidentiality towards the Customer.